Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global steel wire rope market was valued at USD 9345.29 Million in 2025. Surging deep-sea exploration contracts and offshore wind installations are fuelling demand for corrosion-resistant steel wire ropes, particularly those with polymer coatings and enhanced fatigue resistance for maritime operations. As a result, the market is expected to grow at a CAGR of 3.40% during the forecast period of 2026-2035 to reach a value of USD 13055.64 Million by 2035.

The continuous growth in the market is sustained by booming infrastructure, mining, and deepwater offshore projects around the globe. One standout government initiative fuelling impacting the global demand is India’s National Infrastructure Pipeline (NIP), under which over 8,000 infrastructure projects have been announced with an investment of nearly USD 4.51 trillion by 2030. This massive push for ports, railways, and logistics directly influences steel wire rope market growth. Additionally, in the United States, the Bipartisan Infrastructure Law signed in 2021 has earmarked over USD 110 billion for roads, bridges, and critical transport upgrades, areas where heavy-lifting wire ropes are essential. Hence, these government initiatives have compelled manufacturers to come up with advanced ropes that can combat high-tension environments.

Additionally, technological integrations, like IoT-based wear sensors embedded into ropes are gaining traction in the steel wire rope market. Companies are integrating smart solutions that notify wear-and-tear in real time, preventing accidents and downtime. These developments indicate a shift towards smarter, safer, and more efficient steel ropes.

Base Year

Historical Period

Forecast Period

Compound Annual Growth Rate

3.4%

Value in USD Million

2026-2035

*this image is indicative*

Renewed importance in offshore wind farms and subsea projects is redefining the steel wire rope market trends. For example, the United Kingdom committed to 50GW offshore wind by 2030, is driving growth in marine construction, where ropes are essential for tasks like mooring and cable-laying. Specialised corrosion-resistant ropes are being developed for saltwater durability, such as those with galvanised and plastic coatings. German firms are developing ropes with integrated tension sensors. These sensors offer real-time data on load, which is important for maintaining subsea tension lines and preventing breakage.

The steel wire rope market dynamics is further boosted by innovations such as embedded RFID chips and wear sensors. Companies like South Korea’s Chung Woo Rope Co. are also launching innovative ropes equipped with load telemetry systems. These smart ropes reduce unplanned downtimes and improve worker safety, aligning with stricter OSHA compliance in the United States and similar agencies globally.

The rise in automated cranes, port loaders, and robotic construction platforms has increased the adoption of steel wire ropes tailored for automation. These advanced systems require ropes with uniform tensile properties, minimal elongation, and high flexibility to ensure precision and consistency in automated operations. Manufacturers are also innovating with fatigue-resistant materials, smart coatings, and advanced braiding techniques to meet the needs of automation.

Massive infrastructure programmes are driving demand in the steel wire rope market globally. For instance, China’s Belt and Road Initiative (BRI), covering over 70 countries, boosts construction and logistics, where hoisting and cable systems rely heavily on high-grade steel ropes. The European Commission also offers a EUR 800 billion recovery fund, where transport and port upgrades require heavy-duty lifting solutions. Such initiatives foster real, measurable growth and open up long-term supply contracts for wire rope manufacturers.

International trade and logistics have also contributed to the steel wire rope market expansion. As international trade grows, the market observes a greater need for proper transportation and logistics. The use of steel wire ropes in ships, as well as proper handling and cargo movement, demonstrate the importance of these ropes in the global economy. Moreover, with global seaborne trade projected to reach 12.5 billion tons by 2030, ports are upgrading cargo systems and cranes, while heavily relying on advanced steel wire ropes for enhanced safety, load-bearing capacity, and reduced downtime.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The EMR’s report titled “Global Steel Wire Rope Market Report and Forecast 2026-2035” offers a detailed analysis of the market based on the following segments:

Market Breakup by Type of Lay

Key Insight: Regular lay remains the largest category in terms of the steel wire rope market share due to its stronghold across civil infrastructure and mobile lifting equipment. Its ease of splicing, inspection, and resistance to rotation makes it the preferred choice in global crane operations. With EU’s Circular Economy Plan pushing for products with longer usable lives, these ropes align with the regulatory and economic requirements for bulk buyers.

Market Breakup by Strand Pattern

Key Insight: Filler wire ropes occupy a substantial share of the steel wire rope market value due to their broad adoption in elevators, cranes, and mobile handling systems. Their capability to distribute load evenly across strands ensures long service life in urban and industrial applications. This reliability drives their appeal in high-frequency operations. Additionally, with rapid urban infrastructure growth, especially in metro rail projects and high-rise buildings, governments are increasingly investing in dependable lifting systems. For example, India’s Smart Cities Mission includes over 7,188 projects, many involving vertical mobility solutions, further boosting demand for filler wire ropes in both commercial construction and public transportation sectors.

Market Breakup by Steel Type

Key Insight: Galvanised steel considerably boosts the steel wire rope market growth due to its balance between cost-efficiency and corrosion resistance. As maritime and construction sectors push for longer life cycles, the zinc-coated wire ropes continue to be the industry’s preferred steel type. Their durability, ease of maintenance, and adaptability across rugged environments make them particularly suitable for projects exposed to harsh weather conditions, heavy loads, and constant mechanical stress.

Market Breakup by Coating Type

Key Insight: Zinc coating strengthens the steel wire rope demand forecast as it offers convenience, cost, and corrosion resistance for industrial and infrastructural applications. It has become the baseline for tender applications in areas of corrosive environments, including marine docks/bridges/mining pits. The galvanised coating protects the steel core from rust and mechanical wear, which helps extend a rope’s operating life, even when directly exposed to water, dust, and abrasion for a long period of time.

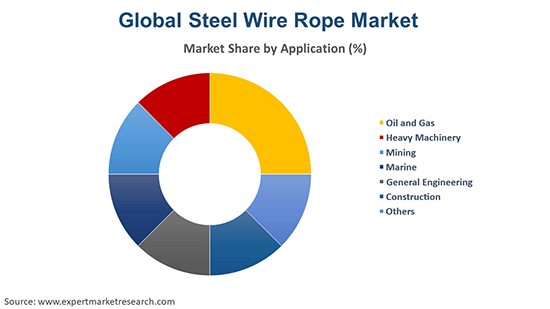

Market Breakup by Application

Key Insight: The oil and gas sector continues to be the dominant application contributing to the steel wire rope market value, bolstered by the hefty lifting requirements that surface and subsurface rigs go through. Moreover, due to continuous exploration in remote areas and deep waters, the sector demands high-performing steel wire ropes that can endure the stress, moisture, and dynamic variations in load, in tasks such as drilling, mooring, and riser tensioning systems.

Market Breakup by Region

Key Insight: The dominance of the Asia Pacific steel wire rope market is driven mostly by rapid urbanisation, industrialisation, and infrastructure development, particularly in China and India. Huge expenditures in building and transportation in this region are also increasing the demand for lifting and rigging solutions. Additionally, growth in the mining sector in Australia and Indonesia has increased the demand for robust steel wire ropes.

By Type of Lay, Regular Lay Accounts for the Dominant Share of the Market

Regular lay ropes have been the go-to option for construction and civil projects due to their lateral stability. Their consistent performance in tower cranes and hoists makes them a staple in long-term government infrastructure projects like India's Bharatmala and Smart Cities Mission. These ropes are also easier to inspect and maintain, aligning well with safety mandates from occupational health regulators worldwide. Further, their dominance is secured due to their reliable performance under moderate rotational stress, which is critical in vertical lifting.

As per the steel wire rope market report, lang lay ropes are gaining ground in sectors requiring enhanced wear resistance and higher flexibility, mainly for mining, oil rigs, and marine dredging. Unlike regular lay, these ropes provide better fatigue resistance during repetitive operations. South African mining firms, facing deeper excavation challenges, have adopted lang lay steel wire ropes. Moreover, these ropes are now being engineered with zinc-aluminium coatings, which makes them suitable for underwater usage.

By Strand Pattern, Filler Wire Hold the Leading Position in the Industry

Filler wire patterns hold the leading position in the market due to their higher flexibility and resistance to deformation under crushing loads. In regions like Europe and Southeast Asia, where hydraulic elevators and industrial lifts are booming, these ropes offer smoother operation and less internal friction. These have become popular in urban logistics hubs, where container handling and automated systems demand continuous, shock-free performance, further propelling the steel wire rope market opportunities.

Warrington ropes, featuring alternating large and small wires, are witnessing a resurgence in heavy-duty applications where balance between strength and flexibility is needed. North American bridge retrofitting projects are increasingly specifying Warrington designs. These ropes offer better load distribution and fatigue resistance, which makes them ideal for long-span cable-stayed bridges. In addition, studies confirm that Warrington ropes can extend lifecycle significantly over single layer ropes in cold environments.

By Steel Type, Galvanised Steel Secure the Largest Share of the Market

Galvanised steel ropes dominate the global market revenue. These are mainly used in high-corrosion environments like marine transport and construction. Their zinc coating acts as a durable shield against rust and mechanical wear. United States coastal logistics systems and Southeast Asian shipyards now prefer galvanised ropes for dockyard cranes and mooring systems. These ropes also offer longer maintenance cycles and comply with corrosion testing standards, which makes them apt for coastal and humid regions.

The market is witnessing surging stainless-steel wire rope demand stemming from food-grade applications, clean rooms, and aquaculture farms. Their hygienic surface and chemical resistance make them ideal for operations where contamination is a risk. Norway’s aquafarming sector, for instance, has increased adoption of stainless-steel ropes for net anchoring and lifting feeds.

By Coating Type, Zinc Occupies a Substantial Market Share

Zinc-coated steel wire ropes hold the dominant position in the global industry due to superior anti-rust performance. These are heavily used in bridge construction, mining lifts, and port cranes. In the United States, DOT projects for bridge renewal now specify zinc-class ropes for suspension systems. Their affordability, high adhesion, and tested compliance with ASTM B117 salt spray tests make them suitable for mass public infrastructure, boosting the overall growth in the steel wire rope market.

PVC-coated ropes are gaining popularity in industries requiring aesthetic appeal and surface protection, like entertainment rigging, zip-lines, and light cargo lifts. Their smooth finish and UV resistance reduce wear on pulleys and human contact points. These ropes are mostly employed in theme parks and indoor arenas in Europe, where noise reduction and visual blending are valued.

By Application, Oil and Gas Boasts the Biggest Market Share

The oil & gas sector significantly drives the market value with extensive rig hoisting, mooring, and anchoring demands. Offshore platforms in the Gulf of Mexico and North Sea heavily rely on high-performance wire ropes capable of handling extreme loads. Recent discoveries in Guyana and Brazil are unlocking fresh orders, with exploration depths demanding high-fatigue, corrosion-resistant ropes tailored for underwater performance.

Modernisation of mining operations, especially in Latin America and Australia, is driving demand in the steel wire rope market. Open-pit mines and shaft excavations require steel ropes with higher breaking loads and resistance to abrasive wear. Autonomous hauling and lifting systems are being increasingly integrated with sensor-equipped ropes, improving operational safety and efficiency.

By Region, Asia Pacific Has Emerged to be the Dominant Region in the Market

Asia Pacific commands the largest share in the global industry due to massive infrastructure activity in India, China, and Southeast Asia. Ongoing urban rail, port logistics, and real estate projects are key demand engines. In China alone, the ongoing Yangtze River Economic Belt project covers 11 provinces and involves several lifting applications which require wire ropes. Furthermore, provincial governments are speeding up the development of industrial corridors and upgrading port facilities, which suggests that the demand for steel wire will be sustained in the coming years.

North America represents a rapidly growing market for steel wire ropes, owing to the strong demand for such items in the construction, oil and gas, and mining industries. The developed infrastructure in the United States, as well as investment in maintenance and enhancements are the key motivators of the market growth. The rising concern about safety rules and compliance drives the demand for high-quality wire ropes. Profit margins are expected to be influenced by variables such as volatile raw material prices and intense competition.

The industry is transitioning from a volume-based market to a value-based market with smart technologies, specialty coatings, and specialty applications changing the overall dynamics. Leading steel wire rope market players are entirely focused on developing engineered ropes, embedded sensor technology, and sustainable manufacturing. These advancements create opportunities for load monitoring in real time, predictive maintenance, and improved safety plans. Furthermore, the increased use of digital twin technology and AI-based diagnostics is transforming the market.

Furthermore, steel wire rope companies find opportunities by offering lifecycle services, digital fatigue tracking, and OEM partnerships. Firms that invest in R&D for corrosion resistance and remote monitoring are well-positioned to lead the market. Expanding after-sales support, training services, and localised supply networks also enhances customer loyalty and market positioning.

Cortland Limited, founded in 2005, manufactures high-performance, heavy-lifting synthetic and steel wire ropes that are critical for offshore applications. Cortland specialises in rope solutions for the oil and gas, marine and defence sectors with customised ropes, tension monitoring systems, and corrosion-resistant coatings.

Anchor Industries Pty Ltd, founded in 1944, based in South Africa, offers high-quality specialty wire rope solutions for mining, construction, and industrial lifting sectors. The company also delivers solutions for turnkey lifting needs and rope testing, to help clients manage risk and downtime for the client, in high-risk performance environments like deep mining shafts, and large volume infrastructure.

Samson Rope Technologies, Inc. is a pioneering synthetic and hybrid wire rope innovator founded in 1878 and based in Ferndale, Washington. The company serves the marine, arborist, and utility industries by providing lightweight, high-strength alternatives to traditional wire ropes.

Chung Woo Rope Co. Ltd, located in Busan, South Korea, manufactures many types of steel wire ropes that address the construction, shipbuilding, and logistics industries. Chung Woo Rope is known for high-precision rope winding technology, and corrosion-resistant coatings that ensure a long-term viable solution in coastal and industrial environments.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other key players in the market are Teufelberger Holding AG, Fasten Group, and Bekaert Group, among others.

Explore the latest trends shaping the global steel wire rope market 2026-2035 with our in-depth report. Gain strategic insights, future forecasts, and key market developments that can help you stay competitive. Download a free sample report or contact our team for customised consultation on steel wire rope market trends 2026.

Sub Saharan Africa Steel Wire Rope Market

South Africa Steel Wire Rope Market

Bright Steel Wire Rope Market

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

In 2025, the steel wire rope market reached an approximate value of USD 9345.29 Million.

The market is projected to grow at a CAGR of 3.40% between 2026 and 2035.

The market is estimated to witness a healthy growth in the forecast period of 2026-2035 to reach about USD 13055.64 Million by 2035.

Key strategies driving the market include investing in sensor technology, localizing production, collaborating with OEMs, expanding marine-grade offerings, and integrating lifecycle maintenance tools.

Key trends of the market are favourable characteristics of steel wire rope like excellent resistance to impact, durability, high strength, abrasion, and corrosion resistance and growing disposable incomes.

The leading types of lay in the market are regular lay, lang lay, and alternate lay.

The leading coating types of steel wire rope in the market are vinyl, zinc, nylon, and PVC, among others.

The significant applications in the market are oil and gas, heavy machinery, mining, marine, general engineering, and construction, among others.

The major players in the global steel wire rope market are Cortland Limited, Anchor Industries Pty Ltd, Samson Rope Technologies, Inc., Chung Woo Rope Co. Ltd, Teufelberger Holding AG, Fasten Group, and Bekaert Group, among others.

The key challenges hindering companies in the market are high raw material costs, fluctuating steel prices, and safety compliance.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Type of Lay |

|

| Breakup by Strand Pattern |

|

| Breakup by Steel Type |

|

| Breakup by Coating Type |

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Strategic Solutions for Informed Decision-Making

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share