How Tungsten Is Strengthening Aerospace Manufacturing

The choice of materials plays a critical role in determining the safety, durability, and efficiency of aerospace manufacturing processes. Tungsten continues to be one of the most vital metals in this sector. Its exceptional properties,such as an extraordinarily high melting point, density, and resistance to wear,make tungsten indispensable in the production and design of aerospace systems. Whether in aircraft engines, satellite components, or space electronics, tungsten ensures that systems maintain optimal performance even under the most demanding conditions.

As aerospace technologies rapidly evolve, encompassing everything from commercial space travel to satellite development and advanced aircraft, tungsten’s role in manufacturing is becoming increasingly significant. Governments, space agencies, and manufacturers are relying on it to meet these complex and stringent demands.

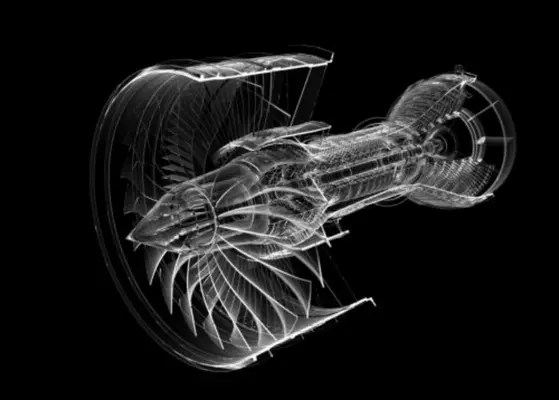

Engines Designed for Extreme Heat and Durability

Materials used in aerospace engines must be able to withstand intense heat without losing strength or shape. Tungsten alloys answer this need perfectly in critical engine parts such as turbine blades, nozzles, and combustion chambers. Their stability under high temperatures promotes greater fuel efficiency and safer operation.

Tungsten composites also serve as balancing materials in jet engines, minimizing vibrations which extends the lifespan of rotating components. Space propulsion systems depend on tungsten alloys to endure the extreme thermal stresses they encounter in operation. These applications highlight tungsten’s trustworthiness when performance and safety cannot be compromised.

Structural Stability and Protective Uses

Thanks to its high density, tungsten serves as an ideal material for maintaining balance and stability in aircraft structures. Tungsten alloy counterweights are strategically applied in wings, rudders, and helicopter rotor blades, improving flight control and reducing risks associated with imbalance during long flights.

Another vital use of tungsten in aerospace is radiation shielding. The metal’s density allows it to effectively protect delicate aerospace instruments from harmful space radiation, making it especially valuable in satellites and exploratory missions. As the frequency of satellite launches and deep-space expeditions rises, tungsten’s shielding role grows even more crucial.

Electronics and Space Systems

Modern aerospace depends heavily on robust electronic systems. Tungsten’s electrical conductivity and resilience make it a prime choice for manufacturing electric contacts and semiconductor components that perform reliably in harsh space environments. These tungsten-based parts help satellites, navigation equipment, and communication devices function continuously without failure.

The demand for smaller, more powerful electronic units in space drives the need for compact but tough materials, and tungsten fits this requirement well. Its combination of strength and conductivity is key in creating lightweight components required to meet the stringent constraints of spacecraft design.

Real-World Tungsten Applications in Aerospace

Many contemporary aerospace projects underscore tungsten’s importance. Private spaceflight firms like SpaceX incorporate tungsten parts in engine components and protective systems. NASA’s longtime use of tungsten alloys in shuttle missions illustrates the metal’s critical role in managing heat and safeguarding equipment in space.

In aviation, tungsten alloys contribute to vibration reduction and stability through their use in counterweights for commercial aircraft. Helicopter manufacturers rely on tungsten components within rotor systems to maintain balance during high-speed maneuvers. These examples reflect tungsten’s widespread impact across diverse aerospace manufacturing disciplines.

Advances in Tungsten Processing and Application

Recent technological advances are unlocking new possibilities for tungsten in aerospace. Additive manufacturing, or 3D printing, using tungsten powders allows for the production of complex parts with reduced material waste and tailored properties. This innovation lowers costs and supports design flexibility tailored to aerospace’s rigorous requirements.

Hybrid materials formed by combining tungsten with lighter metals are emerging to address concerns about weight while preserving tungsten’s strength and durability. Such composites aim to improve performance without sacrificing efficiency, crucial as aerospace moves toward greener and more sustainable technologies.

Policy and Investment Driving Tungsten Use

The aerospace industry's reliance on tungsten is reinforced by a combination of technological progress, government funding, and private investment. Defense and space programs financed by organizations like the U.S. Department of Defense and the European Space Agency consistently incorporate high-performance materials such as tungsten.

Private companies also build long-term agreements with tungsten suppliers to ensure steady access to high-quality materials. This synergy between manufacturers and the metal industry fosters innovation while stabilizing supply chains critical to aerospace’s future growth.

Tungsten’s Essential Role in Aerospace’s Future

As the aerospace sector faces new challenges, from electric-powered aircraft to reusable spacecraft, tungsten remains a cornerstone material. Its unmatched heat resistance, strength, and dependability make it difficult to replace for components that must perform flawlessly under extreme conditions.

Despite ongoing research into alternative materials, tungsten’s unique attributes ensure it remains central to aerospace manufacturing. Moving forward, the metal is expected to play an even greater role as the industry prioritizes performance, safety, and sustainability.

For comprehensive insights on trends, investments, and forecasts, refer to our Global Refractory Metals Market

Tungsten: The Metal That Powers Innovation

Tungsten continues to be an irreplaceable asset in aerospace applications. From engine parts to structural components and cutting-edge space electronics, it enables aerospace technologies to reach new heights while maintaining safety and efficiency. Its vital role extends beyond traditional uses, fueling commercial and spaceflight advancements, readying the industry for tomorrow’s challenges.

Share