Are Abaca-Reinforced Biocomposites the Future of Eco-Friendly Automotive Interiors?

As automakers globally continue their efforts to produce lighter and more eco-friendly vehicles, which is a significant factor for electric vehicles (EVs), they are also looking for sustainable materials that can substitute plastic and fiberglass. Abaca fiber is one of the pieces of the puzzle in this transition as it is the main component of biocomposites used in producing interior parts of a vehicle such as panel doors, dashboards, trunk liners, and the underside of the floors.

The report on the global demand for abaca fiber states that automotive and transportation will be the fastest-growing sectors that utilize abaca fibers as a result of the trend to make vehicles lighter and emit fewer gases. To deliver the double benefit of enhanced structural performance and meeting the environmental challenges posed by regulations and consumer preference, manufacturers turn to composites reinforced with abaca.

Why Are Abaca Composites Gaining Traction?

- High Strength-to-Weight Ratio: Abaca fibers rank among the most robust natural fibers, and the result of their combination with thermoplastic resins (e.g., polypropylene) is a composite that has good tensile and flexural strength, in some cases equal to that of the traditional composites but with half the weight.

- Fuel Efficiency & Emissions Reduction: The use of abaca-based materials to substitute heavier plastics or glass-fiber composites will help automakers to bring down the total weight of the vehicle, thus improving fuel economy or extending the mileage of electric vehicles.

- Sustainability & Recyclability: In contrast to synthetic fibers, abaca is a renewable and biodegradable resource. Its utilization is in line with corporate environmental-related goals, the consumer trends towards green products, as well as tight sustainability regulations in regions like Europe.

- Versatility in Applications: Automakers globally have integrated abaca-reinforced composites for vehicle floor paneling, trunk covers, and other interior components, and their use has been extended to different vehicle models.

Real-World Adoption & Industry Players

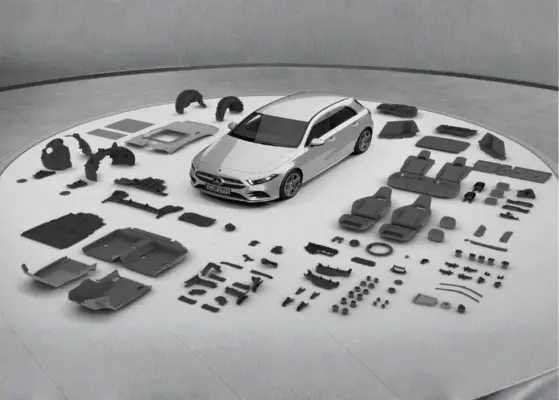

A polycentric situation such as the European one is a manifestation of the scenario of abaca-based components adoption which involved not only vehicle manufacturers but also compound material innovators that comprise the supply chain. There is indeed an example production model formed by a natural-fiber supplier partnering with a big automaker, in which abaca-reinforced polypropylene composites are utilized in under-floor components and spare-tire well covers. One clear case of this is the collaboration of Mercedes-Benz with natural-fiber specialists in Germany and the Philippines, where the abaca-reinforced polypropylene composites were introduced in the production models of the A-Class and B-Class for parts in the under-floor area and spare-tire wells to make the vehicle lighter, more durable, and lessening the CO2 emissions. This cooperation showed that the abaca fibers could satisfy the strict automotive performance standards, thereby giving the go-ahead to a more widespread use by the mobility sector and composite-materials innovators in Europe.

Among others, Asian automakers have been procuring abaca fibers for vehicle interiors and this is a news-worthy development. One recent example is Toyota's sustained sourcing of Philippine abaca fiber that is used in select models' interior components where the fiber is blended into reinforced plastics for panels and trim. Corresponding to that, Mitsubishi as well as a handful of Southeast Asian EV startups, have experimented with abaca-based composites to produce lightweight interior parts.

Such efforts reveal the increasing trend in Asia towards natural fibers which are capable of achieving weight reduction, sustainability rating improvement, and stricter material traceability demands in new vehicle platforms originations. On the other hand, composite material manufacturers are setting up their production lines to combine abaca with bio-resins or thermoplastics, thus the company targets entry-level components such as door panels, dashboards, and trunk liners.

Challenges: Material Processing, Cost, and Supply Consistency

One of the main problems in the automotive industry application of abaca is the need for processing of natural-fiber composites because these fibers require a particular way of production to solve the problem of adhesion between the fiber and polymer matrix. Thus coupling agents (e.g., MAPP, MAPE) are generally used to provide good mechanical performance and long life.

Supply consistency, on the other hand, is still an issue as abaca farming is very geographically limited, and this may cause the quality of the fibers or the supply chain to be unstable. For the auto industry that demands high volume and high consistency of parts, this variation calls for strict quality control protocols to be followed.

At last, if abaca composites are mostly used for weight and emission reduction purposes, their costs in terms of a single unit (specially for high-quality, automotive-grade parts) can be still a bit more than that of the conventional plastics, at least until a large scale and widespread usage have been fulfilled.

What This Means for the Future of Automotive Materials?

As a result of environmental regulations becoming more stringent, consumer demand for sustainability getting stronger, and the increasing production of EVs, to which lightweight materials are more beneficial, it is well-positioned that abaca-based biocomposites will be able to make the transition from a niche market to a mainstream one. The material abaca might turn into a regular one for interior plastic replacement if more vehicle manufacturers take the pledge of "green interiors".

If the manufacturers and material suppliers put their investments into dependable supply chains, uniform processing methods, and solid quality control, abaca-reinforced composites could be vehicles that we see every day in the near future, thus achieving a win-win situation of environmental and performance goals.

Explore market trends and growth forecasts for abaca fiber across industries in the Abaca Fibre Market

Looking Ahead: Toward Greener, Lightweight Vehicles

With the automotive sector undergoing a change, it is highly probable that substances like abaca, which is not only a renewable but also a strong and light material, will be the main players in the transition to vehicles that are both sustainable and efficient. The coming of regulatory measures, the consumer's desire for eco-friendly interiors, and the advancement of composite technologies, are just some of the reasons why abaca-reinforced biocomposites are the likely material of the next generation of automotive interiors.

Share