Environmental and Sustainability Trends in India’s PCB Industry

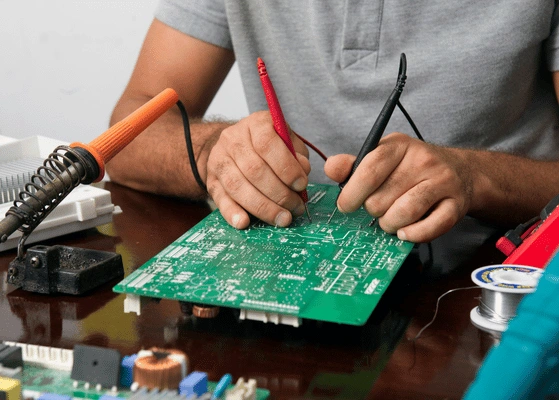

As India’s printed circuit board (PCB) market grows, so does the focus on sustainability and environmental responsibility within the industry. The electronics manufacturing sector worldwide is increasingly adopting eco-friendly materials, waste reduction practices, and regulatory compliance to minimize environmental impact. India’s PCB industry is following suit, recognizing that sustainability is not only a regulatory requirement but also a competitive advantage in global markets.

Rising global awareness around climate change, stricter environmental laws, and growing consumer preference for greener products are reshaping how PCBs are designed and manufactured. From sourcing lead-free solder and recyclable laminates to optimizing energy use in factories, Indian PCB makers are taking steps that align with both environmental priorities and business growth. This blog examines the emerging environmental and sustainability trends in India’s PCB sector, highlighting how manufacturers are innovating to meet stricter standards, reduce waste, and incorporate green practices into production.

Shift Toward Eco-Friendly Materials

A major sustainability trend in the Indian PCB industry is the gradual shift toward eco-friendly materials. Traditionally, PCB manufacturing relies on materials such as epoxy resins, lead-based solder, and halogenated flame retardants, which pose environmental and health risks during production and disposal.

To reduce hazardous substances, Indian manufacturers are increasingly adopting lead-free solder and halogen-free laminates. These materials comply with global standards like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, enabling Indian PCBs to meet export market requirements.

The use of bio-based resins and recyclable substrates is also under exploration by some firms aiming to develop greener PCBs. Although still in nascent stages, these innovations could significantly lower the carbon footprint of PCB manufacturing in the long term.

Effective Waste Management and Recycling Practices

PCB fabrication generates various types of waste, including chemical residues, metal scrap, and defective boards. Managing this waste responsibly is crucial to prevent environmental contamination.

Leading Indian PCB manufacturers are implementing wastewater treatment plants to neutralize hazardous chemicals before discharge. Efforts to recover copper from scrap boards and reuse it in manufacturing processes are gaining traction, reducing raw material consumption.

Recycling defective or end-of-life PCBs is also being encouraged. Although formal recycling infrastructure is limited, industry groups and policymakers are pushing for greater awareness and systems to reclaim valuable metals like gold, silver, and copper from discarded PCBs.

Compliance with Environmental Regulations

India’s regulatory framework for PCB manufacturing is evolving to incorporate stricter environmental guidelines. Compliance with national laws on hazardous waste management, air and water quality, and chemical handling is mandatory for PCB producers.

To cater to global customers, Indian PCB makers are aligning with international regulations such as RoHS and ISO 14001 (Environmental Management System). Achieving these certifications enhances market access, particularly in Europe, North America, and Japan.

Regular environmental audits, employee training, and transparent reporting are becoming integral to PCB manufacturing operations, reflecting a growing culture of corporate social responsibility.

Efficiency and Carbon Footprint Reduction

Energy consumption is a significant concern in PCB manufacturing, given the high-power demand of production equipment and environmental control systems. Indian PCB firms are increasingly investing in energy-efficient machinery and lighting systems to lower operational costs and emissions.

Some manufacturers are integrating renewable energy sources such as solar power within their facilities to reduce dependence on grid electricity. This not only supports sustainability goals but also improves energy security in regions with unstable power supply.

Reducing the overall carbon footprint through efficient resource use and supply chain optimization is becoming a priority, especially for companies targeting global markets with stringent environmental expectations.

Industry Collaboration and Innovation for Sustainability

Sustainability challenges require collective action. Indian PCB industry associations, research institutions, and government bodies are collaborating to develop best practices, technical guidelines, and innovation roadmaps for greener PCB manufacturing.

Workshops and training programs focused on sustainable manufacturing processes, chemical safety, and waste management are becoming more common. These initiatives help small and medium manufacturers upgrade their operations in line with environmental norms. Apart from this, technology innovation plays a vital role, with research into biodegradable substrates, waterless processing, and advanced recycling techniques ongoing in academia and industry.

For an extensive overview of India’s PCB market, including sustainability trends, see our India Printed Circuit Board (PCB) Market

Sustainability Shapes India’s PCB Future

The future of India’s PCB industry hinges on balancing growth with environmental stewardship. Embracing eco-friendly materials, efficient waste management, regulatory compliance, and energy conservation not only reduces ecological impact but also strengthens the industry's global competitiveness. As consumer and regulatory pressures mount, sustainable manufacturing will become a defining characteristic of successful PCB producers in India and beyond.

Share