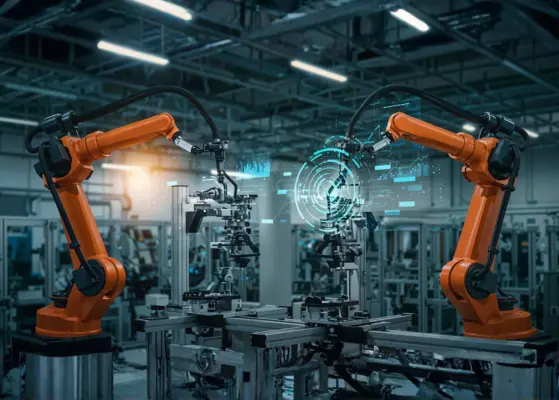

How Is IoT Driving Smarter Manufacturing and Industrial Growth?

The manufacturing industry is witnessing a huge change as Internet of Things technology links machines, systems, and workers together in a single digital ecosystem. Smart factories rely on sensors in tools to gather performance data such as temperature, vibration, pressure, and output levels. A constant flow of information reveals to manufacturers the very core of production processes. Thus, teams become capable of spotting inefficiencies, raising throughput, and keeping quality at a steady level. Manual inspections and reports, which are a day or two behind schedule, are no longer the only option available to plant management. Because of their real-time dashboards, which show problems as they appear, operations can always stay on course.

Moreover, this connected platform fosters flexible manufacturing models that can quickly respond to changing demand. Production turns can be altered based on inventory levels or customer orders, which leads to less stock being left over and better delivery timetables. The industrial sectors are becoming more competitive, so IoT prepares manufacturers to have higher agility in their operations as well as lower running costs.

Predictive Maintenance Reduces Downtime and Cost

Unscheduled equipment breakdown is still one of the costliest problems in industrial operations. Old-style maintenance methods rely on predetermined fixed service intervals or on fixing after a breakdown, which most of the time leads to very expensive production stoppages. IoT brings in predictive maintenance through the deployment of sensors that continually monitor the health of a machine. Such systems check and analyze vibrations, heat, and power usage patterns to forecast component degradation and thus, avoid failures.

Once certain levels are hit, maintenance crews are notified so that repairs can be done during scheduled downtime instead of emergency stoppages. This way, equipment lasts longer, the stock of spare parts is minimized, and the safety of workers is enhanced as dangerous breakdowns are avoided. Gradually, the manufacturers have an excellent insight into the performance of the equipment, which is a great help in smart investment decisions and long-term capital planning. Besides saving costs and minimizing downtime, predictive maintenance (PdM) also enhances the overall equipment effectiveness (OEE) of the production lines. Manufacturing plants have recorded the benefits of this data-oriented method in fewer production stoppages, lower repair costs, and increased output.

Real-Time Monitoring Enhances Quality Control

With IoT-based monitoring systems, manufacturers can check whether the production quality meets the desired standards regularly. Through the placement of sensors on assembly lines, they can get the information regarding cycle times, defect rates, and material usage. By using centralized platforms, teams can spot anomalies quickly, and managers are able to review interruptions. In situations where quality issues arise, the team on the ground can trace the source of the problem and, through corrective beneficial actions, prevent the occurrence of large batches of defective products.

Further, there are automated inspection tools equipped with connected cameras and measuring devices that perform quality checks. These can detect even the smallest defects, dimensional errors, and packaging inconsistencies very accurately. Hence, continuous monitoring helps in lowering the amount of waste and, at the same time, is a guarantee for products to comply with regulatory as well as customer requirements. The real-time availability of production information also facilitates continuous improvement programs. By analyzing past performance, manufacturers get process refinement, layout optimization, and workforce efficiency increase. All this results in a feedback loop that keeps the progress steady across the entire operation.

Supply Chain Visibility and Inventory Optimization

Besides the manufacturing floor, IoT helps supply chains to be more aligned. Shipment monitoring through connected tracking devices provides continuous updates on the location, temperature, and handling conditions of the cargo. This is critical for goods that are sensitive, such as electronics, chemicals, and pharmaceuticals. Based on the data, manufacturers can work on preventing losses, managing delays, and improving communication with distributors and customers.

Inventory systems also benefit from real-time stock monitoring, which enables automated reordering and demand forecasting. Thus, warehouses minimize the amount of stock while always having essential parts at their disposal. Sharing the visibility of the suppliers and logistics partners at the same time allows better planning and stronger collaboration throughout the value chain. Such features empower manufacturers to be more agile, deliver faster in the event of a scarcity, and stay operational without interruption, even when the situation is very uncertain. With the growing complexity of supply networks, IoT is the key to transparency that helps to keep the manufacturing operations resilient and efficient.

For deeper insights into industrial IoT adoption, regional trends, and investment outlooks, explore the Global IoT Market Report.

Building the Future of Connected Industry

The Internet of Things (IoT) is setting the stage for sophisticated industrial features such as digital twins, analytics supported by artificial intelligence, and self-governing production systems. All these devices and supply chains continuously generating data are the lifeblood for these innovations. On the other hand, a combination of top-notch cybersecurity measures and flawless integration of existing infrastructures is necessary for the achievement of the desired results.

By acquiring scalable platforms and training the workforce, manufacturers equip themselves to realize the full potential of the Internet of Things in the long run. As the industrial sectors are pressured into raising the production volume and at the same time lowering the environmental footprint, the connected technologies are providing the right tools for enhancing efficiency and sustainability. Smart manufacturing is not a future vision anymore. It comes as a normal approach for those organizations that, through digital transformation, seek to become more resilient and gain a competitive edge in the rapidly digitalized industrial field.

Share