Understanding What Determines Aluminum Production Growth in Mexico

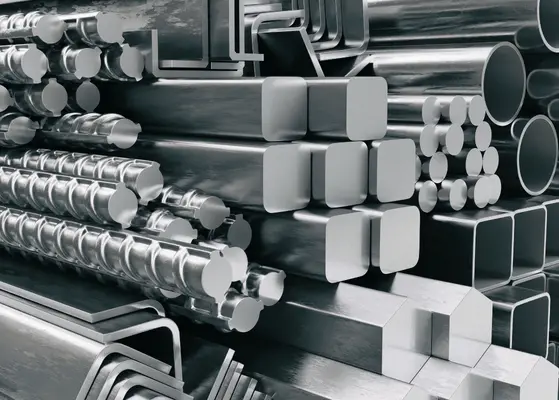

The aluminum industry in Mexico has been witnessing a very big and stable growth for 10 years now, with demand being the major driver from different industrial markets. The automotive industry, which is the primary consumer of aluminum, is at the forefront of this trend, as car manufacturers are continuously turning to aluminum products to achieve weight reduction, fuel efficiency, and lowering of carbon emissions besides complying with strict environmental regulations. Aluminum body panels, chassis parts, engine components, and structural parts are being utilized more and more in cars as the world changes to environmentally friendly production methods.

Meanwhile, the construction sector is also a significant demand driver for the aluminum industry. Aluminum is used in building frames, roofs, windows, doors, facades, and curtain walls, among other applications, due to its longevity, resistance to corrosion, and aesthetic qualities. The growing consumption of aluminum in large-scale institutional building projects for commercial buildings, bridges, airports, and public offices is also playing a role in this. Besides that, aluminum is turning out to be a master of all trades as it is used in packaging and electronics like cans, foils, and electronic devices, which means it can be used in multiple ways. Such overall industrial demand provides sure consumption to the production giving strong support for level growth of long-term.

Technological Developments in Manufacturing

Groundbreaking technology is one of the leading factors that are causing a change in aluminum production in Mexico. Modern smelting technology, automation of the casting process, and the use of more advanced alloy compositions are all booming their efficiencies, consumption of energies are being cut, and quality is improving. Firms are embracing smart manufacturing systems, IoT-enabled instruments, and riding on the predictive maintenance software to bring down stoppages, increase up time of their machines, and save on operational costs.

Similarly, the part of recycling and green technologies is just as important. Over time, aluminum scrap is recycled more to reduce the use of new raw materials and to conserve energy. Efficient recycling systems are not only a big help to the environmental goals but also a sure source of aluminum that is cost-effective. Mexican manufacturers will be able to satisfy high domestic demand, penetrate new foreign markets, and consolidate their competitive position in the global aluminum market with the adoption of such technologies.

Supportive Government Policies and Trade Initiatives

The issue of government policies that favor aluminum production has been developed. Investment incentives, tax benefits, and simplified regulatory approvals are some of the measures that motivate companies both at home and abroad to increase their operations. Simultaneously, sustainability-oriented incentives like zero-emission targets, grants for energy-saving industrial processes, and the provision of clean technologies are acting as factors to attract industry competitiveness.

Trade agreements with the United States, Canada, and other foreign partners, in general, give access to export markets that are both stable and low in cost. Besides that, customs clearance that is efficient, reduced tariffs, and regulatory support that allows manufacturers to work with ease and remain competitive are some of the additional benefits. Overall, trade agreements along with government policies give an investment-friendly and secure environment for a gradual expansion and growth of the aluminum sector in Mexico.

Investment in Infrastructure and Energy Efficiency

The link between infrastructure and the expansion of aluminum production is very close. Development of the Industrial Park, logistics facilities, and advanced port facilities, among others, contribute to the alleviation of supply chain restraints that lead to the timely delivery of raw materials as well as final products. The improved transportation network has made it possible for producers to supply aluminum to both the domestic and foreign markets at reasonable prices.

Moreover, energy efficiency is also on the top of the list. Aluminum production is very energy-intensive, so it is a must that the energy used should be renewable and when it comes to energy recovery, it should be maximized and the production process should be energy-efficient. Companies that have and continue to invest in these activities are reaping the rewards as they are cutting their costs, positioning their brands as sustainable, and are still able to compete in both the domestic and international markets. Energy optimization, combined with a robust infrastructure, not only lays the foundation for production at capacity over the long-term but also meets even higher environmental standards.

Emerging Applications and Market Innovation

The characteristics that make aluminum a very attractive option to be used in multiple ways are the very same ones that keep on opening new avenues of growth. Apart from the traditional sectors, the use of aluminum in aerospace, clean energy, and advanced electronics has been growing rapidly due to its lightness, strength, and recyclability. The demand for high-performance aluminum products is being accelerated by the development of electric vehicles, green construction projects, and green packaging solutions. The need to invest in research and development to take advantage of such openings is another point.

The producers of innovating materials, composites, and advanced production processes decided to put their energy in research and development to make the products fit the applications of new industries and stay ahead of competitors in the market. By adapting production strategies to industrial needs that keep on evolving, Mexico's aluminum sector not only improves its global standing but also paves the way for sustainable development and innovation.

Discover more about the rise and the potential of the Mexico Aluminium Market in our comprehensive report

Building a Stronger Aluminum Future for Mexico

The aluminum industry in Mexico is on the path of prolonged growth, where many factors such as increasing industrial demand, cutting-edge production technology, forward-looking government policies, and applications in multiple sectors are working in harmony to produce such a result. Individually, these elements offer a favorable business environment for producers, investors, and consumers, collectively they create a dynamic environment for producers, investors, and customers. The industry will continue to be competitive as well as sustainable if it adopts advanced technologies, achieves higher energy efficiency, and harvests new applications. With long-term development and strategic implications, Mexico is becoming more and more of a key player in the global aluminum market that is beneficial to all parties involved.

Share