PCB Manufacturing Techniques and Innovations in India

The India printed circuit board (PCB) market is witnessing a significant transformation driven by advancements in manufacturing techniques and materials. The evolution from simple single-layer boards to complex multilayer, flexible, and high-density interconnect (HDI) PCBs is reshaping the Indian electronics landscape. Supported by growing domestic demand, government incentives, and a focus on quality, India is emerging as a promising hub for PCB production capable of catering to diverse sectors such as consumer electronics, automotive, telecommunications, and healthcare.

Traditionally, Indian PCB manufacturing was largely limited to basic boards with manual or semi-automated processes. However, the increasing complexity of electronic devices requiring miniaturization, higher speeds, and reliability has pushed Indian manufacturers to adopt advanced technologies and upgrade capabilities. This blog explores the key manufacturing techniques and innovations that are driving India’s PCB industry forward, setting the stage for enhanced global competitiveness.

From Traditional to Advanced Production Techniques

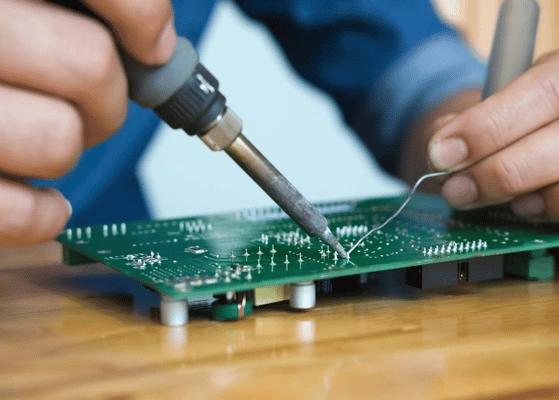

Earlier, PCB manufacturing in India involved labor-intensive steps such as manual drilling and chemical etching, which restricted precision and scalability. Today, automation is rapidly taking over these manual processes, introducing greater accuracy, efficiency, and repeatability.

Computer Numerical Control (CNC) drilling machines have become essential, enabling precise hole drilling on multilayer boards where alignment tolerances are stringent. Laser Direct Imaging (LDI) technology has largely replaced traditional photolithography, allowing highly detailed and complex circuit patterns on smaller footprints. This shift is critical for producing HDI PCBs that feature fine lines and microvias required in smartphones, IoT devices, and telecom equipment.

Automated Optical Inspection (AOI) systems are widely used in quality control to detect defects early in the production line, reducing rework and waste. Flying probe testers and X-ray inspection machines further ensure the integrity of connections within densely packed multilayer boards, which are otherwise difficult to inspect visually.

Growing Focus on Multilayer, Flexible, and Rigid-Flex PCBs

The Indian PCB market is seeing rising demand for multilayer boards, which allow electronic circuits to be stacked vertically, reducing device size while enhancing performance. Multilayer PCBs are essential in applications such as automotive electronics, telecom infrastructure, and medical devices, where complex functionalities must fit compactly.

Flexible PCBs, which use bendable substrates like polyimide, are gaining importance for their adaptability in wearables, automotive sensors, and portable gadgets. The ability to conform to three-dimensional shapes makes them indispensable for modern electronics. Indian manufacturers are investing in flexible PCB production lines to tap into this growing opportunity.

Additionally, rigid-flex PCBs, combining rigid and flexible layers, are increasingly produced in India for aerospace, defense, and advanced medical applications. These boards offer design flexibility and durability, supporting highly integrated electronic assemblies.

Material Innovations Enhancing Performance and Reliability

Material selection plays a critical role in PCB functionality. The dominant substrate material, FR-4 epoxy glass, continues to be widely used for general applications due to its cost-effectiveness and good electrical properties. However, Indian PCB makers are now incorporating advanced materials such as Rogers, PTFE, and ceramic-filled laminates for high-frequency and high-speed applications, including 5G communications and radar systems.

Surface finish technologies are also advancing, with Electroless Nickel Immersion Gold (ENIG) becoming the preferred choice for its excellent solderability and corrosion resistance. Organic Solderability Preservatives (OSP) provide a cost-effective alternative for surface protection in less demanding applications. These material enhancements improve the durability and longevity of PCBs produced in India, increasing their acceptance in stringent export markets.

Government Initiatives and Industry Collaboration

The Indian government’s initiatives like the Production Linked Incentive (PLI) scheme for electronics manufacturing are catalyzing investments in PCB manufacturing technology upgrades and capacity expansions. Infrastructure development in electronics manufacturing clusters facilitates easier access to modern equipment and raw materials.

Skill development programs and collaboration with research institutions help address the talent gap for operating sophisticated manufacturing processes. Partnerships between academia and industry foster innovation in PCB materials, design, and manufacturing methods, propelling the ecosystem toward higher value-added production.

Outlook: Innovation Fuels Growth and Global Competitiveness

With the rapid growth of India’s electronics sector, demand for complex and specialized PCBs is rising sharply. Manufacturers that adopt advanced production techniques and invest in quality improvements are better positioned to serve domestic OEMs and tap into export markets.

The increasing adoption of multilayer, flexible, and rigid-flex PCBs, combined with improved materials and automation, signals a maturing industry capable of meeting evolving technology requirements. As government support and industry collaboration intensify, India’s PCB manufacturing sector is set for robust expansion, contributing to reduced import dependence and a stronger electronics value chain.

For comprehensive market insights, visit our India Printed Circuit Board (PCB) Market

Innovative Production Technologies Will Continue Boosting PCB Manufacturing in India

India’s PCB manufacturing is undergoing a critical transformation fueled by advancements in production techniques, material innovation, and quality assurance. These changes enable Indian PCB makers to produce complex, high-performance boards that meet global standards. Supported by government policies and industry-academic collaboration, India is poised to emerge as a significant player in the global PCB supply chain, driving growth and technological self-reliance in the electronics sector.

Share