Rubber Manufacturing Innovations Revolutionizing Global Industries

Rubber is a vital commodity material used in industries across the globe, ranging from automobile tires and industrial components to healthcare equipment and consumer goods. Conventional rubber production has contributed to fulfilling increasing demand, but usually at the expense of environmental and operating drawbacks. High energy consumption, generation of wastes, and the ecological footprint of plantations have prompted the industry to find new ways of doing things.

Innovations in rubber production aim to increase efficiency, enhance product quality, and minimize environmental footprint. Manufacturers everywhere are investing in new processing methods, eco-friendly materials, and digital technologies. These innovations are revolutionizing production practices, making the rubber industry more responsible, responsive, and in line with world sustainability standards.

Advanced Processing Techniques

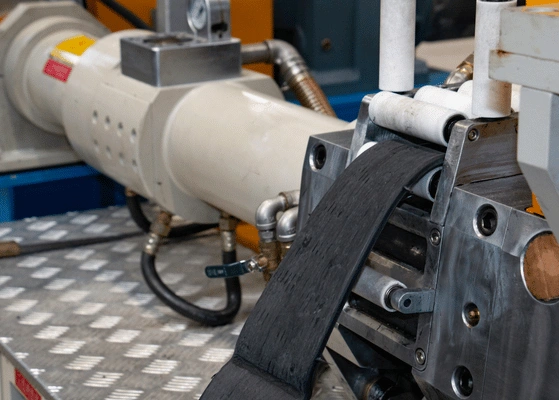

Contemporary rubber production enjoys new processing techniques that increase quality and efficiency. Continuous vulcanization, computerized mixing, and high-precision extrusion devices increase production rate without compromising consistency. These processes minimize material loss, save energy, and reduce operating expenses.

Additive manufacturing, also known as 3D printing, is increasing its presence in rubber production. It enables accurate, customized parts to be produced with minimal material consumption. Medical devices, cars, and consumer products industries can make small batches cost-effectively without creating waste inventory. This cost-saving flexibility reduces environmental impact.

Chemical innovations also improve rubber performance. New stabilizers, accelerators, and fillers make them more durable, flexible, and resistant to heat and chemicals. These developments prolong product lifespans, lower replacement rates, and prevent waste. Manufacturers using these innovative techniques together can compete in the global industry while supporting sustainability.

Sustainable and Green Solutions

Sustainability is the core of contemporary rubber production. Recycling schemes, bio-based additives, and power-saving equipment are being implemented by companies. Waste is minimized, and natural resources are saved by reclaiming old tyres, industrial wastage, and household items and recycling them into new ones.

Plant-based substitutes like dandelion latex and guayule are being researched. These crops can thrive in varied climates, lessening the dependence on tropical rubber plantations as well as preserving forests. Companies are trying mixtures of recycled, synthetic, and natural rubber to retain product performance with reduced environmental effect.

Energy efficiency continues to be high on the agenda. Plants across the globe are adopting renewable energy, heat recovery technologies, and equipment optimization to minimize carbon footprint. Green strategies not only help preserve the environment but also generate cost advantages and build brand equity in competitive international markets.

Digital Transformation and Smart Manufacturing

Digital technologies are making rubber manufacturing a more efficient and responsive operation. Intelligent sensors track equipment performance, forecast maintenance, and schedule production to reduce downtime, boost productivity, and save on operating expenses.

Data analysis enables the manufacturer to detect inefficiency, enhance product uniformity, and minimize wastage. Sophisticated software facilitates monitoring raw materials, checking for environmental compliance, and guaranteeing sustainable sourcing. The tools provide a clear view of the supply chain that is trustworthy and reliable, providing assurance to buyers regarding the sustainability of the purchased products.

Automation is being increasingly used in mixing, shaping, and curing rubber. Robotic precision executes repetitive work with high precision, minimizing errors and ensuring quality. Human workers are also able to concentrate on innovation, oversight, and ongoing improvement. The confluence of automation, intelligent monitoring, and data analysis makes rubber production more agile, efficient, and eco-friendly.

Global Industry Adoption and Market Trends

Globally, sectors are adopting rubber manufacturing innovations to remain competitive and achieve sustainability goals. The automotive sector is relying more on bio-based elastomers for tires and interior parts. The healthcare and medical sectors are using nitrile and other synthetic rubbers to create safe, long-lasting, and hypoallergenic products.

On the other hand, consumer brands are launching green footwear, sports gear, and home goods made from mixtures of recycled and renewable plant-based rubber. Asian manufacturers are testing smart factories with automation, IoT, and green energy to minimize ecological footprint. European and North American firms are embracing the circular economy model to recycle scrap rubber and lengthen product life cycles.

Market trends reveal that firms emphasizing sustainable and innovative manufacturing of rubber acquire a competitive edge. Customers become more environmentally conscious, affecting purchasing behavior. Governments also implement regulations that promote responsible production. These factors collectively speed up global uptake of innovative rubber manufacturing practices.

For full insights into product innovation, adoption trends, and growth opportunities, explore our Natural Rubber Market

Pioneering a Responsible and Innovative Future

Technological advancements in rubber production are remodeling the industry globally. It encompasses sophisticated processing techniques, environmentally friendly practices, and digital technologies that build production systems that are effective, trustworthy, and environmentally sound. Manufacturers can make effective rubber products while minimizing environmental degradation and retaining resources.

All these innovations also advantage society and employees through improved safety conditions, training, and economic growth. Global businesses are exposed to high-performance products, and consumers enjoy environmentally friendly options. The future of the rubber manufacturing industry is in harmonizing innovation, sustainability, and operational excellence. By embracing new technologies, green materials, and intelligent manufacturing techniques, the industry can continue to expand responsibly while preserving the planet for generations to come.

Share