How Technological Innovations Are Redefining the Machining Centers Market?

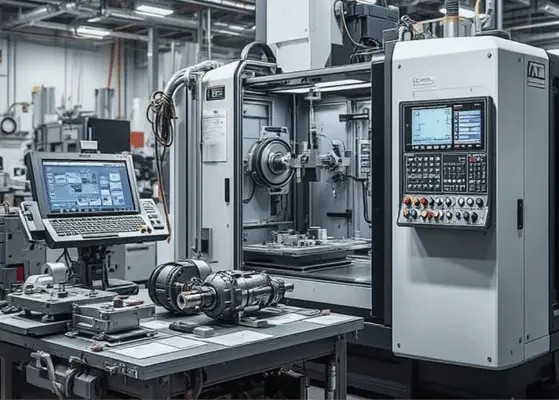

Manufacturing today is no longer about scale alone but also intelligence, flexibility, and precision. Machining centers are now experiencing a wave of innovation that is redesigning how manufacturers tackle production.

As global industries face the pressure to deliver faster, more precise, and sustainable outputs, technology developments in machining centers are making the difference.

From AI-driven predictive maintenance to hybrid machining systems, the industry is undergoing an unprecedented shift. For B2B customers and decision-makers, it is not simply about remaining current, it is about guaranteeing long-term competitiveness in a marketplace where technology adoption increasingly determines survival.

Automation and AI Take the Lead

Automation has been a part of machining for decades, but the entry of AI has taken it to the next level. Today's machining centers incorporate AI-based algorithms that adjust cutting speeds, tool paths, and power consumption in real-time.

For instance, machine-learning-based predictive analytics can identify tool-wear patterns, helping to minimize downtime and extend equipment life. Aerospace and automotive manufacturers are among the earliest adopters, as unplanned downtime in these sectors can result in significant financial losses.

Machining centers that use AI are also boosting worker productivity, with more time spent on value-added activities and less time on manual adjustments.

Digital Twins Are Revolutionizing the Game

The idea of digital twins including virtual copies of real-world assets is being applied extensively to machining centers. With digital twins, manufacturers are able to simulate production runs, identify areas of inefficiency, and experiment with different configurations without interrupting processes.

This technology boasts significant impact on industries like aerospace and medical devices, where tolerances are nearly zero. Digital twins enable firms to test precision prior to actual machining, reducing waste and enhancing first-pass yield.

Japanese and European leading machine tool manufacturers are already integrating digital twin features into their new machining center products, an indicator that this technology is rapidly transitioning from early adoption to broad application.

Hybrid Machining Centers Gain Ground

The emergence of hybrid machining centers, where additive manufacturing (3D printing) is blended with conventional subtractive processes, is another key trend in the market. Together, they enable the manufacture of complex shapes as per exact requirements.

Hybrid machines are being applied in toolmaking, repair of aerospace components, and prototype building. They reduce waste and improve production cycle times, providing both cost and sustainability benefits.

In North America and Asia Pacific, hybrid machine centers are being piloted in R&D facilities and gradually expanded for commercial applications. Their acceptance is a part of the larger shift toward adaptable, multi-functional manufacturing machinery.

Energy Efficiency and Sustainability Are Priorities

Sustainability has emerged as an indispensable concern for manufacturers globally. Recent machines are being developed with energy-saving motors, regenerative drive technology, and coolant recycling systems.

These innovations not only lower operational expenses but also complement the increasing focus on environmental, social, and governance (ESG) metrics. Suppliers of environmentally friendly machining centers are gaining market advantage with customers who are concerned about green certifications and sustainability goals in their supply chains.

Connectivity Through Industry 4.0

Another defining trend is the embedding of machining centers into more expansive smart factory systems. With IoT-connected sensors and cloud-based connectivity, machines are now able to talk to other systems in order to facilitate predictive maintenance, quality assurance, and real-time monitoring of production.

For instance, a machining center in a car factory can input operational data into a central MES (manufacturing execution system), and plant managers can make real-time adjustments across production lines. Such a connectivity is improving overall equipment effectiveness (OEE) and facilitating the global move toward data-driven manufacturing.

For an in-depth analysis of technology adoption, see our Global Machining Centers Market

Innovations Are Redrawing Competitive Patterns

Technology improvements are becoming key strategies in the machining centers industry. Those that do not embed AI, digital twins, or hybrid capabilities risk lagging behind competitors that are quicker to adopt.

For manufacturers in aerospace, automotive, medical devices, and precision engineering, being able to produce more output with fewer resources and more precision will be the ultimate differentiator. Suppliers that concentrate their offerings on these areas are likely to lead, while those who do so after a while will find it difficult in an increasingly innovation-driven market.

Share