Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global manufacturing operations management software market was valued at USD 13.79 Billion in 2025. The industry is expected to grow at a CAGR of 9.00% during the forecast period of 2026-2035 to attain a valuation of USD 32.65 Billion by 2035.

Base Year

Historical Period

Forecast Period

Only 43% of small and medium-sized enterprises (SMEs) use advanced software to track and manage their inventory.

In 2024, it is anticipated that 42% of warehouses and distribution centers will make investments in automation and technology.

61% of pharma executives in the US use big data and analytics to manage their work operations.

Compound Annual Growth Rate

9%

Value in USD Billion

2026-2035

*this image is indicative*

Manufacturing operations management (MOM) software is a type of software that helps manufacturers optimise their production processes, improve product quality, reduce costs, and increase efficiency. MOM software integrates various aspects of the manufacturing process, including R&D management, advanced planning and scheduling, product quality management, production capacity analysis, and inventory management.

Some of the factors that are driving the manufacturing operations management software market growth are the increasing demand for automation, digitalisation, and smart manufacturing, the need for enhancing operational visibility and traceability, the rising adoption of cloud-based and mobile solutions, and the growing regulatory compliance and environmental concerns.

Deployment of cloud-based solutions and growing need for inventory management tools are factors propelling the manufacturing operations management software market growth

| Date | Company | Announcement |

| February 2024 | Aspen Technology, Inc. | Commitment to achieving net-zero operations by 2030. Offering AspenTech Operational Insights for fast, confident decision-making. |

| February 2024 | Cadence Design Systems, Inc., Dassault Systèmes | Integration of AI-driven Cadence OrCAD X and Allegro X with Dassault Systèmes’ 3DEXPERIENCE Works portfolio for best-in-class collaboration. |

| January 2024 | ABB Ltd. | Significant investment in software engineering and AI-based applications. Acquisition of majority of Meshmind’s assets to expand R&D capabilities in Industrial IoT, AI, and machine vision. |

| December 2023 | ABB Ltd. | Strengthened partnership with Volvo Cars to provide more than 1,300 robots for the construction of the next-generation electric vehicles. |

| Trends | Impact |

| Deployment of cloud-based solutions | More flexibility, security, and accessibility for manufacturers, as they can access their software from any device, location, and time. Cloud-based solutions also reduce the need for hardware maintenance, software updates, and data backup. |

| Rising demand for automated technologies, such as artificial intelligence (AI) | Smart automation, predictive analytics, and quality control for manufacturers, as they can use AI and ML to automate repetitive tasks, forecast demand, detect anomalies, and improve quality. AI and ML can also help manufacturers learn from data, improve decision making, and enhance customer satisfaction. |

| Emergence of Internet of Things (IoT) and Industry 4.0 | Real-time connectivity, data-driven insights, and innovation for manufacturers, as they can connect their machines, devices, and people in a networked system. IoT and Industry 4.0 can help manufacturers monitor, control, and optimise their operations, and leverage new opportunities, such as predictive maintenance, smart logistics, and customised products. |

| Focus on sustainability and circular economy | Reduced environmental impact, waste, and costs for manufacturers, as they can adopt new business models that extend the life cycle of their products and materials. Sustainability and circular economy can help manufacturers reduce their resource consumption, emissions, and disposal, as well as increase their revenues, customer loyalty, and social responsibility. |

The need for next-generation software that integrates real-time data analysis, cloud computing, and industrial mobility is anticipated to create new opportunities for players in the manufacturing operations management software market. The improved economic conditions have prompted businesses to look for methods to boost productivity and optimise their operations, which has sped up the adoption and creation of software-based solutions like MOM software.

The software makes it easier for information to move from the shop floor to the rest of the organisation, improving visibility and enabling real-time control and operational adjustments. Through real-time metrics, it can also identify and send alerts, set off alarms, or automatically shut down machines when necessary. The manufacturing operations management software market outlook is anticipated to be positively impacted by real-time metrics, which aid in the analysis of load patterns, production requirements, and resource demands for energy savings.

The increased need for value from data and sophisticated connectivity across the value chain is also expected to drive the manufacturing operations management software market growth. Moreover, MOM software is a vital tool for manufacturers looking to streamline their operations, improve productivity, and increase efficiency. It provides an integrated, data-driven approach to managing manufacturing operations, offering real-time insights, enabling proactive decision-making, and streamlining various processes to enhance overall efficiency and productivity. The wide range of benefits offered by this management software is expected to accelerate the manufacturing operations management software market development in the forecast period.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Global Manufacturing Operations Management Software Market Report and Forecast 2026-2035 offers a detailed analysis of the market based on the following segments:

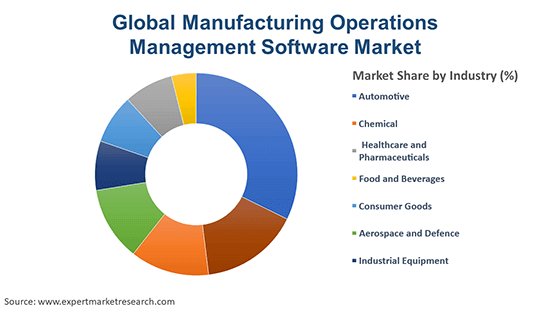

Market Breakup by Industry

Market Breakup by Functionality

Market Breakup by Enterprise Size

Market Breakup by Region

Automotive industry holds a significant market share as the software helps reduce downtime

According to manufacturing operations management software market analysis, the automotive industry is one of the major end-users of manufacturing operations management software, as it requires efficient coordination and synchronisation of various processes and resources across the supply chain. Manufacturing operations management software helps automotive manufacturers to optimise production planning and scheduling, reduce waste and downtime, improve quality and compliance, and enhance customer satisfaction.

Other industries such as the chemical industry faces various challenges such as stringent environmental regulations, complex production processes, fluctuating raw material prices, and high energy consumption. Manufacturing operations management software enables chemical manufacturers to streamline and automate their operations, enhance operational visibility and traceability, ensure safety and compliance, which increases the manufacturing operations management software market value in the chemical industry.

Meanwhile, the healthcare and pharmaceutical industry is anticipated to lead the manufacturing operations management software market share in the forecast period as it requires high levels of quality, accuracy, and compliance in its manufacturing operations, as any error or deviation can have serious consequences for human health and safety. Manufacturing operations management software helps healthcare and pharmaceutical manufacturers to manage and monitor their production processes, ensure regulatory compliance and quality standards, manage inventory, and facilitate data-driven decision making.

SMEs and large enterprises contributes majorly to market growth for efficient work operations

SMEs may have limited resources and budget to invest in complex and expensive software solutions, but they also need to improve their operational efficiency and competitiveness in the global market. Therefore, they may prefer cloud-based, scalable, and affordable manufacturing operations management software that can meet their specific needs and challenges.

Some of the key factors driving the demand for manufacturing operations management software among SMEs are the need to reduce operational costs, enhance quality, optimise production planning and scheduling, comply with regulatory standards, and integrate with other enterprise systems.

On the other hand, large enterprises may have more complex and diverse manufacturing processes and operations, involving multiple plants, locations, products, and customers. They may also have more stringent requirements for security, reliability, performance, and customisation of their software solutions. Therefore, they may opt for on-premises, hybrid, or multi-cloud deployment models of manufacturing operations management software that can offer them more control, flexibility, and functionality.

According to the manufacturing operations management software market report, some of the factors increasing the value of manufacturing operations software among large enterprises are the need to improve operational visibility, agility, and collaboration, leverage data and analytics for decision making, automate and streamline workflows, and align with strategic goals and objectives.

The market players are increasing their collaboration efforts and partnership activities to gain a competitive edge in the market.

| Company Name | Year Founded | Headquarters | Products/Services |

| ABB Ltd. | 1988 | Zurich, Switzerland | Electrical equipment, industrial automation, robotics, power grids |

| Aegis Software Company | 1997 | Philadelphia, United States | Manufacturing execution system (MES) software |

| Aspen Technology, Inc. | 1981 | Bedford, United States | Process optimisation software, asset performance management software |

| Critical Manufacturing | 2009 | Porto, Portugal | Industry 4.0-ready MES software, IoT and big data solutions |

Other key players in the manufacturing operations management software market include Dassault Systèmes, The Emerson Electric Co., and Epicor Software Corporation, among others.

North America is one of the prominent regions because it has a strong industrial base

North America is the largest market for manufacturing operations management software as the region has a robust industrial base and a high rate of adoption of cutting-edge technologies like cloud computing, artificial intelligence, and the internet of things, which facilitate the integration and optimisation of manufacturing operations. The presence of leading players, such as Siemens, ABB, Honeywell, and Rockwell Automation, also contributes to the manufacturing operations management software market growth in North America.

Europe also has a mature market for manufacturing operations management because the region is home to some of the major manufacturing sectors, such as automotive, aerospace, pharmaceutical, and chemical, which require efficient and agile operations management solutions. The increasing focus on sustainability, quality, and compliance, along with the rising demand for customised products, also drives the manufacturing operations management software market expansion in Europe.

Meanwhile, Asia Pacific is the fastest-growing market as the region is witnessing rapid industrialisation and urbanisation, which creates a huge potential for the adoption of manufacturing operations management software. The growing investments in smart manufacturing, digital transformation, and industry 4.0 initiatives, especially in China, India, Japan, and South Korea, also increases the overall manufacturing operations management software market size in Asia Pacific.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market is expected to grow at a CAGR of 9.00% between 2026 and 2035.

The major drivers of the market include the increasing population, growing need for inventory management tools, rising construction industry, and the growing need for energy conversation.

Operations management oversees the transformation of resources into goods and services.

MOM software is a type of software that helps manufacturers plan, execute, monitor, and optimise their production processes. MOM software can integrate with various systems, such as enterprise resource planning (ERP), quality management system (QMS), supply chain management (SCM), and industrial Internet of Things (IoT).

Key trends aiding market expansion include the rising demand for operational efficiency to improve the quality of the manufacturing process, high deployment of cloud-based solutions, and rising demand for AI and ML technologies.

North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa are the leading regions in the market.

The leading industries are automotive, chemical, healthcare and pharmaceuticals, food and beverages, consumer goods, aerospace and defence, and industrial equipment, among others.

The significant functionalities are inventory management, labour management, manufacturing execution system (MES), process and production intelligence, and quality process management, among others.

The major enterprise sizes in the market are small and medium enterprises (SMEs) and large enterprises.

Key players in the market are ABB Ltd., Aegis Software Company, Aspen Technology, Inc., Critical Manufacturing, Dassault Systèmes, The Emerson Electric Co., and Epicor Software Corporation, among others.

In 2025, the market attained a value of nearly USD 13.79 Billion.

The market is estimated to witness a healthy growth in the forecast period of 2026-2035 to reach about USD 32.65 Billion by 2035.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Industry |

|

| Breakup by Functionality |

|

| Breakup by Enterprise Size |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Strategic Solutions for Informed Decision-Making

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share