Advances in LED Heat Sink and Thermal Management Technologies

Innovation in thermal management is quickly becoming one of the defining factors in the global LED downlight market. As commercial spaces demand higher lumen outputs, longer operational life, and lower maintenance costs, manufacturers are redesigning downlights with advanced cooling geometries and smarter driver technologies to keep junction temperatures in check. As a result, the heat sink is no longer a basic aluminum block but a strategic design element that directly affects efficiency, safety, and long-term performance.

This change has led to an increase in R&D budgets being allocated by lighting brands and has encouraged collaboration between lighting and materials manufacturers, thermal simulation software providers, and semiconductor manufacturers to produce more robust lighting fixtures.

Therefore, with the trend toward buildings operating around the clock, the thermal performance of LED downlights will continue to be a top priority for all commercial, industrial, and retail applications.

Advanced Aluminum and Ceramic Heat Sinks Gain Industry Momentum

For many years, aluminum has been the primary metal used to create heat sinks for LED fixtures, however, the demand for high lumen outputs with low thermal increases has driven the need for continued development of new materials. Companies like Cree Lighting, Signify and Hubbell Lighting have incorporated premium grade forged aluminum, graphite composite and ceramic heat sinks into their downlight offerings. In addition, ceramic-based heat sinks have gained popularity because they provide excellent thermal conductivity coupled with high levels of electrical insulation.

Such material upgrades are enabling manufacturers to launch next-generation downlights with lower junction temperatures, helping extend LED life cycles above 50,000–60,000 hours even in high temperatures.

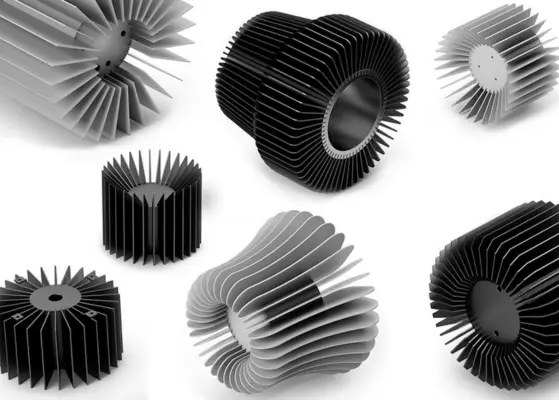

Innovative Fin Geometries Improve Airflow and Heat Dissipation

Designing heat sinks using advanced computational fluid dynamics to simulate heat movement through a product’s fixture has evolved into a complex science involving the experimentation with new fin geometries and other innovative means for facilitating optimal heat dissipation in smaller, compact-style fixtures. Examples of these fin types include spider web, tapered, cross-flow, and ring-style radiator configurations.

Moreover, many manufacturers, such as Acuity Brands, the Zumtobel Group, and Delta Light have developed heat sink designs that take advantage of natural convection to minimize the need for large aluminum masses. Since these designs are much lighter than traditional aluminum heat sinks, they allow for optimum performance of downlights even if they are installed in shallow ceilings or enclosed soffits where traditional heat sinks struggle to attain thermal discharge.

Driver Thermal Improvements Reduce Failure Rates

While much of the thermal discussion focuses on heat sinks, the LED driver remains a major point of failure in commercial lighting. Companies are addressing this by enhancing driver thermal protection, improving component layout, and integrating next-generation capacitors.

Manufacturers such as Tridonic, Inventronics, and MEAN WELL have developed drivers with:

- Higher-temperature-rated electrolytic capacitors

- Over-temperature shutdown circuits

- Spread-spectrum switching that reduces thermal hotspots

- Optimized PCB spacing to enhance airflow

Due to the rise of thermal interface materials (TIMs) and Thermal Interface Coatings (TIMCs), downlights are becoming increasingly reliable across all applications of commercial lighting. Companies are developing LED downlights that will survive even under the most extreme and long-term thermal conditions.

Brands like Nichia, Seoul Semiconductor, and Bridgelux are working closely with TIM suppliers to build LED modules with smooth thermal pathways, reducing thermal resistance and improving lumen maintenance. Many modern downlights now feature:

- Ceramic-coated MCPCBs

- High-conductivity interface pads

- Anti-oxidation coatings to improve long-term stability

These TIM enhancements help maintain consistent thermal performance even after years of operation. Several commercial lighting manufacturers report that upgrading TIM materials alone improved system-level reliability to a considerable extent, especially in high-usage environments like malls and airports.

Passive and Hybrid Cooling Solutions Expand Market Opportunities

Although passive cooling is the most common method of cooling commercial LED downlights, a number of hybrid cooling systems are also starting to emerge in high-output cases. Some manufacturers are investigating the particular use of vapor chambers, micro-heat pipes and combination of fan-cooling systems compactly integrated into architectural or high-ceiling environments. Companies such as Philips and Osram are currently performing trials using hybrid cooling systems to provide high performance without increasing the overall size of a fixture.

For deeper insights into market dynamics and product strategies, explore the LED Downlight Market

Thermal Innovation Is Becoming a Key Differentiator for LED Downlight Manufacturers

Manufacturers of LED downlights are actively developing more advanced materials, more efficient heat-sink geometries, and more robust heat sink mounting systems. Their intention is to assist users in achieving maximum energy performance, operating efficiency, and long-term energy cost savings in demanding commercial lighting applications.

For commercial contractors, commercial developers, facility operators, lighting designers and other commercial stakeholders, innovations in thermal management technology will affect their long-term maintenance budgets, energy performance, and installation flexibility. The superior thermal management constructed into the structure of LED downlights will continue to serve as a standard of quality, reliability, and sustainability as buildings evolve to be more technologically advanced, while they also have the potential to provide more value-added service throughout their life cycles.

Share