How Innovations in Pulping and Deinking Are Transforming Paper Recycling Efficiency?

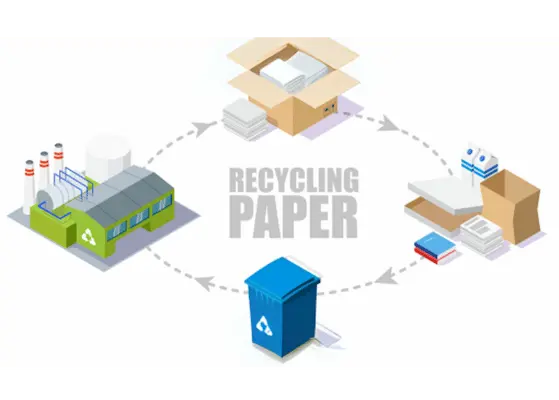

The global recovered paper industry is undergoing a major transformation, driven by two critical processes that define the quality and usability of recycled fibers: pulping and deinking. At the same time, shifting dynamics, ranging from the rise of e-commerce packaging to the decline of traditional print formats and the push for corporate sustainability, are reshaping how paper is used. Advances in fiber recovery technologies are opening fresh avenues of value creation for businesses across the sector.

Why Pulping and Deinking Are More Important Than Ever?

Recovered paper accounts for more than half of the global papermaking raw material, as per industry estimates. But that recycling rate for old wastepaper to useful pulp is entirely dependent upon pulping and deinking efficiency, processes increasingly shaped by automation, chemical innovation, and sustainability-driven design.

Enzyme Based and Low-Chemical Deinking

One of the most promising developments in the market is the use of biotechnology. Enzyme-based deinking has already replaced many traditional chemical-intensive practices, allowing mills to reduce environmental impact while still achieving the required pulp brightness. These enzymes specifically target ink binders, enabling better fiber separation with lower energy consumption.

High-Consistency Pulping Systems

Conventional pulping is associated with a lot of energy requirements and tends to lead to fiber damage and degradation. The application of high-consistency pulping systems is reversing the above problems by reducing the water input but maintaining a higher level of fiber quality. These systems have been found to pulp mixed streams of waste with fewer rejects, an extra advantage with input quality being more variable with removal of global trade barriers around recovered paper.

Digital Automated and Artificial Intelligence in Fiber Recovery

Automated systems have redefined the way pulping and de-inking are implemented. For instance, today there are artificial intelligence-based monitoring systems that track content in the pulping slurry in real time and make dynamic adjustments to chemical dosages and mechanical reactions; this clearly enhances the efficiency of operation and minimizes downtimes and waste and rejects.

Sustainability and Energy Savings at the Forefront

The transition to sustainability has also spurred the demand for energy efficient technology for the pulping and deinking operations. New flotation cells are being engineered for energy input and ink particle recovery. Closed-loop water systems are also being incorporated in deinking lines that can save considerable freshwater usage.

Some North American mill operators indicate they have decreased total energy consumption per tons of recycled pulp by retrofitting their older deinking plants with new flotation and washing technologies. This is not only coinciding with discovering cost reductions but also corporate carbon-reduction goals.

Policy and Market Pressure

These upgrades are unfolding under strong market and regulatory pressures. In Europe, the Packaging Waste Directive is enforcing strict recycling and fiber quality requirements, while FMCG brand owners are pushing for higher recycled content in packaging, compelling mills to improve fiber yield and brightness.

In countries like India, initiatives such as Swachh Bharat and extended producer responsibility are driving investments in new pulping and deinking facilities. For foreign equipment makers and chemical suppliers, this opens compelling opportunities to deliver advanced technology solutions to rapidly growing economies.

For detailed forecasts and competitive insights, explore our Recovered Paper Market

Pulping and Deinking Are Shaping the Future of Paper Recycling

Technological progress in pulping and deinking is steadily redrawing the global paper recycling landscape. From enzyme-based processes that minimize chemical dependency to AI-driven automation that streamlines audits and quality checks, these innovations are pushing mills toward long-term sustainability, higher efficiency, and tighter regulatory compliance.

Early adopters of next-generation pulping and deinking technologies stand to gain more than supply continuity, they strengthen their ESG credentials, improve cost competitiveness, and position themselves as reliable partners within increasingly selective supply chains. As circularity and sustainability gain genuine economic weight, the success of fiber recovery will define the next decade’s market leaders, separating those who adapt quickly from those left behind.

Share