How Refractory Metals Are Driving Electric Vehicle Battery Innovation

The modern electric vehicle revolution is rapidly transforming global transportation. As automakers strive to develop batteries that charge faster, last longer, and operate safely in diverse conditions, a special group of metals has emerged as indispensable: refractory metals. This group includes tungsten, molybdenum, niobium, tantalum, and rhenium,metals known for their resistance to heat, wear, and extreme environments.

These metals are playing multiple critical roles in electric vehicle (EV) battery systems. From structural supports to conductive components, refractory metals help create batteries that are safer, more efficient, and cost-effective,benefitting both manufacturers and consumers alike.

Enhancing Battery Performance with Refractory Metals

Refractory metals contribute significantly to improving the reliability and lifespan of EV batteries. For instance, molybdenum and niobium provide mechanical strength and structural integrity to battery electrodes, enabling repeated charging cycles without rapid degradation. Tungsten, on the other hand, assists in managing the heat produced during charging and discharging, helping prevent battery overheating,a common safety concern.

For drivers and manufacturers alike, these qualities matter. Longer driving ranges on a single charge are highly sought after, and refractory metals play a vital role in making this possible. Their durability also means batteries need fewer replacements over time, saving money and reducing waste.

Safety and Heat Tolerance at the Forefront

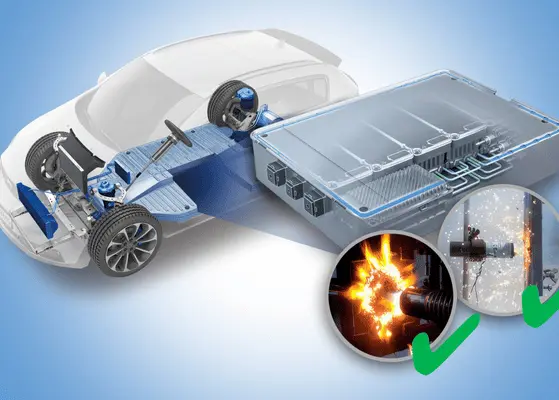

Safety remains a top priority in electric vehicle design. High-capacity batteries generate substantial heat, which must be controlled to avoid hazards like thermal runaway. Refractory metals excel here, able to withstand high temperatures without losing strength or safety.

Tantalum is frequently used in capacitors and electrical connectors, enhancing reliability under heat stress. Tungsten components provide thermal regulation in the most demanding sections of battery assemblies, ensuring stability and protection even under extreme conditions. This marriage of durability and performance makes refractory metals preferred materials in battery safety systems.

Essential Roles in Battery Production

Beyond their function in the battery itself, refractory metals contribute during manufacturing. Components of battery production equipment,such as furnaces used in electrode fabrication,must withstand intense heat; molybdenum and tungsten alloys are ideal materials here. Their resilience supports steady production quality and efficiency, underpinning the entire battery supply chain.

Niobium is also gaining attention as an additive in lithium-ion batteries, enhancing electrical conductivity and enabling faster charging and discharging. These advancements could reduce charging wait times,one of the biggest hurdles blocking wider EV adoption. Refractory metals are thus key enablers in the journey toward more user-friendly electric vehicles.

Industry Adoption Highlights

Major players in the automotive industry actively use refractory metals to boost EV battery performance. Tesla, alongside numerous global manufacturers, invests heavily in advanced battery alloys boasting refractory metal-enhanced electrodes and connectors.

Solid-state battery developers eye niobium-based anodes to extend battery life and boost conductivity. Meanwhile, leading Japanese manufacturers incorporate tungsten heat shields inside battery packs to improve safety margins. European producers cooperate with research institutions to experiment with molybdenum coatings that prolong electrode endurance. These international collaborations illustrate the growing importance and global reliance on refractory metals in EV innovation.

Innovation and the Road Ahead

Technological progress continues to expand refractory metals’ roles in EV batteries. New coating techniques using tungsten and molybdenum reduce wear and lengthen battery service life. Additive manufacturing enables the production of parts precisely tuned for optimal structural robustness and electrical performance.

Research also explores hybrid materials,such as niobium combined with carbon composites,aiming to improve energy density and charge/discharge efficiency. These innovations promise to speed charging times, increase driving range, and strengthen battery robustness, helping EVs compete further with traditional vehicles.

Support from Policy and Investment

Government efforts to promote electric vehicle adoption,including consumer subsidies, charging infrastructure investments, and stricter emission rules,indirectly boost demand for refractory metals by expanding the EV market.

Private enterprises are also securing supply by forging agreements with refractory metal producers to ensure continuous access to these critical raw materials. This proactive approach helps manufacturers meet production targets and mitigate supply chain risks in a highly competitive environment.

Refractory Metals: Powering the Future of Clean Mobility

The future of electric vehicles hinges on battery technology, and refractory metals will remain fundamental to this success. Their unique combination of heat resistance, strength, and conductivity makes them indispensable in both today’s lithium-ion batteries and in emerging technologies.

As engineers and researchers find new ways to integrate these metals, their presence in EV batteries is set to rise. Whether enabling longer driving ranges, faster charging, or enhanced safety, refractory metals stand at the core of the fast-evolving clean mobility revolution.

For deeper analysis of market drivers, supply dynamics, and future trends, explore our Global Refractory Metals Market

Reliable Foundations for an Electric World

Electric vehicles symbolize the shift toward sustainable transportation, and the metals that compose their batteries are just as critical. Refractory metals are emerging as essential allies for manufacturers focused on building batteries that are secure, enduring, and efficient. Their integral role across multiple battery components highlights their importance in advancing clean mobility across the globe.

Share