Fermentation Methods, Craft Production, and Industrial-Scale Processing in Vinegar Production Across the United States

Vinegar has held an important place in American kitchens for hundreds of years for foods, as well as functional products. Behind each bottle, there are complex multi-step production processes, from fermentation, or traditional small scale craft processing to large scale industrial or manufacturing processes. In the United States, consumer preferences for craft and specialty vinegar have evolved and are driving improvements in production processes, while large industrial processes are still providing consistent supply to grocery stores and foodservice outlets. To understand vinegars available to American consumers, it is essential to understand vinegar production processes.

The Heart of Craft Vinegar Lies in Traditional Fermentation

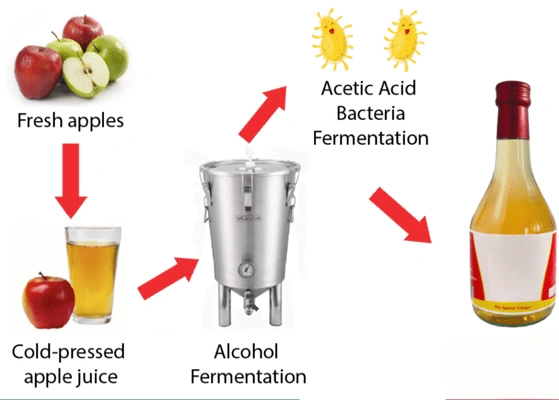

Fundamentally, vinegar is produced by fermentation where ethanol is converted to acetic acid by acetic acid bacteria. Traditional fermentation is used by craft vinegar producers to produce vinegar slowly and naturally. An illustration of the artisanal crafts approach, the "Orleans method" involves aging wine or cider in a wooden barrel to offer rich scents, sophisticated flavor, and general subdued acidity important in the manufacture of artisan apple cider vinegar and balsamic vinegar in the United States.

Craft vinegar makers often highlight their use of raw, unfiltered ingredients and small-batch production. These methods appeal to health-conscious and gourmet consumers who value authentic flavors, probiotic potential, and minimal processing. The emphasis on artisanal techniques has fueled a growing segment of specialty vinegar in urban markets, where chefs and home cooks alike prioritize taste and culinary creativity.

Submerged Fermentation: Industrial-Scale Efficiency

Even though craft manufacture focuses on quality and tradition, the United States vinegar industry is now using a variety of submerged fermentation techniques at an industrial scale to capture the large volume demand. Submerged fermentation allows for a method for converts ethanol to acetic acid by the acetic acid bacteria more quickly when using large stainless-steel tanks capable of constant aeration.

To that end, submerged fermentation is quicker, more predictable, and easier to standardize and scale-up as a process making it well suited for table vinegar, distilled vinegar, and any other commodity vinegar, and every other scalable vinegar. This method is also adaptable to various raw materials, including fruit juices, cereal substrates, and industrial alcohol, making it ideal for producing specialty vinegars as well as high-volume commercial products.

Fruit-Infused and Specialty Production Techniques

Beyond traditional and manufacturing methods, the United States market has seen a surge in specialized vinegars with unique flavor profile. Fruit-infused vinegars, herbal mixes, and wine-based types sometimes use fermentation techniques with maceration or infusion processes. Producers can age a base vinegar with fruits, herbs, or spices to create nuanced aromatic notes suitable for culinary creativity and well-being trends starting with

These specialty vinegars appeal to city consumers seeking natural components, probiotic potential, and multipurpose usage from salad dressings to health tonics. The adaptability of infusion and ageing processes enables producers to make small batch flavors, hence enhancing brand differentiation in a saturated market.

Quality Control, Regulatory Compliance, and Sustainability

Leading vinegar producers in the United States must comply with strict food safety and labelling laws across all production methods. The Food and Drug Administration (FDA) sets standards of identity to ensure federal compliance on the concentration of acetic acid, the transparency of labelled ingredients, and to ensure the fermented product is free from harmful levels of bacteria. Producers should verify fermentation and conditions to assure that product consistency and shelf stability are uniform.

Sustainability is a growing trend in the United States vinegar craft production. Some craft and industrial producers strive to reduce energy use, use by-products in food or for other uses, and use locally sourced fruits or grains. Sustainability is more attractive to some consumers than others. These practices appeal to environmentally conscious consumers but also fall into the functional foods and organic streams.

For a detailed analysis of market trends and production insights, read our United States Vinegar Market

The Future of Vinegar Production in the US

Consumer demand for diversity, flavor, and function is changing strategic production decisions of vinegar producers. Craft methods are gaining traction in health-conscious and gourmet markets, while industrial-scale production assures that direct-to-consumer, retail, and foodservice channels are capable of meeting demand. With technological advancements and skilled fermentation production methods, producers can develop and provide a range of high-quality, safe, functional vinegar products.

As Americans assess the quality of food, transparency about ingredients in food products, and considering versatility and creativity in the kitchen, investment will continue into United States vinegar production toward craft and sustainable methods.

Share