Exoskeletons, often called exosuits, are wearable devices with motorized joints that reduce strain and damage by supporting weight, adjusting posture, and providing lift assistance. Although workers in manufacturing and construction are increasingly using these machines, their primary purpose is physical rehabilitation.

Depending on the body area they are designed for and how they are powered, exoskeletons function differently. While some models employ grasping tools to improve a user's strength, others move weight from one place of the body to another to promote endurance and decrease constant strain. The many kinds of exoskeletons use different methods to do this.

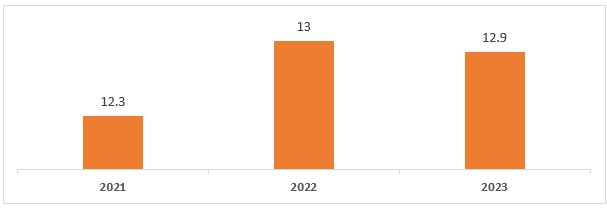

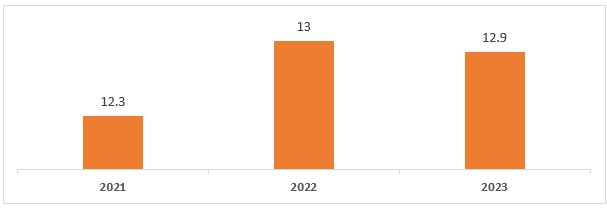

Figure 1: US Construction and Extraction: Fatal Work Injury Rates per 100,000 Full-Time Workers (2021-2023)

Furthermore, it is difficult to establish suitable working conditions in the construction industry because of the distinctive nature of the shifting settings. For construction site workers, exoskeletons can be very beneficial in promoting safety and reducing tiredness. In 2023, the United States' fatal work injury rates in the construction and extraction industries are consistently high at 12.9 per 100,000 full-time workers. Exoskeletons are primarily of two types: can be entirely mechanical or use a combination of electricity and mechanics, depending on the manufacturer. Depending on the suit and its purpose, frames can be made of soft materials like cotton and textiles or strong elements like metal.

1. Mechanical Exoskeletons or Passive Exoskeletons: There's no electricity needed for mechanical exoskeletons. Because these instruments don't require recharging or an external power source, users benefit from extended field life. The majority of mechanical exoskeletons transfer weight from one part of the body, such as the arms and shoulders, to another, such as the waist and core, in order to lessen strain and fatigue.

2. Powered Exoskeletons, also known as Robotic or Active Exoskeletons: Generally speaking, exoskeletons that are partially or completely electric are stronger and can support greater weight than mechanical exoskeletons. When necessary, they can apply greater pressure and strength to more targeted regions. However, if they unexpectedly run out of power, they may slow down operations because they need a power source and time to recharge in between usage.

What Are the Applications of Exoskeletons in Construction?

Exoskeletons are employed in the construction sector for a number of purposes to improve worker well-being, productivity, and safety. By lowering strain and injury risk, the devices can give workers protection, strength, and support when used at your site. All things considered, this vital technology can offer:

- Support for the arms and shoulders

- Support for the back

- Support while standing and crouching

Following are kinds of exoskeleton applications in the construction sector are as follows:

1. Heavy Lifting and Load Handling: Exosuits and powered exoskeletons aid construction workers in lifting and carrying heavy objects, providing mechanical support and reducing strain on muscles and joints, enhancing workplace efficiency and reducing injury risks.

2. Overhead Work and Arm Support: Working with their arm’s lifted overhead is necessary for a variety of construction operations, such as plumbing, electrical wiring, and ceiling panel installation. By giving the arms artificial support and lowering the effort required to maintain them in an elevated position, exosuits with arm support systems might lessen muscle strain and fatigue. When doing overhead jobs, exoskeletons can increase worker comfort and reduce accidents caused by tiredness.

3. Working at Heights and Fall Prevention: Construction workers benefit from exosuits with stabilization systems, which enhance balance, reduce falls, and improve safety by detecting and correcting body movements, thereby reducing the risk of accidents.

4. Ergonomic Support and Posture Correction: Exoskeletons offer ergonomic support on construction sites, promoting posture, reducing strain, and reducing injuries, resulting in improved body alignment, comfort, and long-term musculoskeletal health.

5. Rehabilitation and Injury Prevention: Exosuits can be utilized for rehabilitation, assisting employees in their recovery from wounds and halting additional harm. These devices can provide controlled resistance and assistance, enabling workers to perform rehabilitation activities and progressively restore their strength and range of motion. Exoskeletons can help workers heal and return to work more quickly and safely by supporting focused movements and provide real-time feedback.

6. Personal Protective Equipment Integration: Exoskeletons can be combined with PPE to improve worker safety, providing mechanical support and fall protection in high-risk construction environments. This reduces injuries and enhances compliance with OSHA standards.

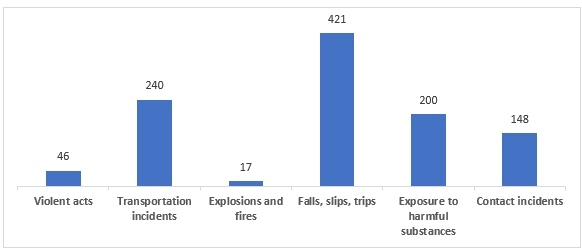

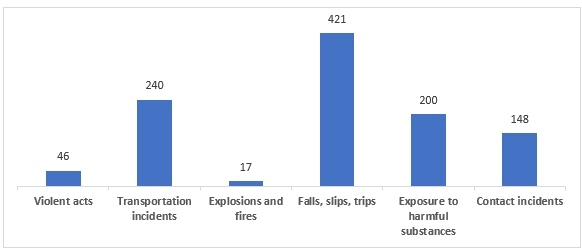

Figure 2: US Construction Industry: Fatal Occupational Injuries Breakdown (2023)

Factors to Consider Before Introducing Exoskeletons on Site

Construction exoskeletons have drawbacks despite their advantages:

- High Initial Costs: As exoskeletons can be costly, smaller businesses may find it difficult to afford their widespread use.

- Acceptance by Workers: Some employees may object to the use of exoskeletons due to discomfort.

- Training Requirements: To guarantee that employees can operate exoskeletons safely and successfully, proper training is necessary.

Recent Development in Construction Exoskeletons Industry

- In January 2025, German Bionic, a leading robotic exoskeleton technology company based in Berlin, is pleased to present the Apogee ULTRA, the most potent exoskeleton ever made in series, which can sustain weights up to 80 pounds (36 kg). Apogee ULTRA, which is currently on the market and is made to empower workers in the manufacturing, logistics, construction, cargo handling, and healthcare sectors, establishes new standards for strength, adaptability, and worker safety while satisfying the demands of a variety of high-intensity jobs and improving productivity.

- In March 2024, HeroWear demonstrates its back-assist exosuit, the Apex 2. The exosuit is lightweight, comfortable, and can reduce muscle tension by 20% to 40% while also reducing muscle weariness by up to 40%. The exosuit has been developed for all-day use, giving users the ability to move and work however they like. Whether users are 5 or 7 feet tall or weigh 100 or 300 pounds, the suit can be tailored to fit a range of body types and is simple to put on and take off.

- In July 2020, in order to create exoskeletal systems, the Hilti Group has partnered with Ottobock SE & Co. KGaA. These technologies represent a future market in the construction sector and open up new avenues for productivity and health protection.

Share